In the automotive industry, the weight of a vehicle plays a crucial role in its overall performance. Lightweight wheels have emerged as an effective way to achieve better handling, acceleration, and fuel efficiency without compromising safety. This article delves into the various aspects of lightweight wheels, focusing on their benefits, materials, fitment considerations, and how they can enhance your driving experience.

Understanding Lightweight Wheels

Lightweight wheels are designed to reduce the overall weight of a vehicle, which can lead to improved performance in several areas. These wheels are typically made from materials that strike a balance between strength and weight savings, allowing for a design that enhances the vehicle’s agility without sacrificing durability.

Benefits of Lightweight Wheels

Choosing lightweight wheels can provide numerous benefits, including:

- Improved Acceleration: Lighter wheels decrease the rotational mass, allowing the vehicle to accelerate faster. This is particularly beneficial in racing and performance driving scenarios.

- Enhanced Handling: Reduced weight improves the vehicle’s handling characteristics, allowing for sharper steering response and better cornering.

- Better Fuel Efficiency: A decrease in unsprung weight (the weight of components not supported by the suspension) can lead to better fuel economy, as the engine does not have to work as hard.

- Reduced Braking Distance: Lighter wheels can decrease the overall weight of the vehicle, resulting in less inertia to overcome during braking, which can lead to shorter stopping distances.

Materials Used in Lightweight Wheels

The choice of material is a significant factor in the performance of lightweight wheels. The most common materials used include:

Aluminum Alloys

Aluminum is one of the most popular materials for lightweight wheels due to its favorable strength-to-weight ratio. Aluminum wheels are not only lighter than steel wheels but also offer better heat dissipation, which is essential for brake performance. Additionally, aftermarket aluminum wheels come in a variety of designs and finishes, allowing for aesthetic customization.

Forged Aluminum vs. Cast Aluminum

There are two main manufacturing processes for aluminum wheels: forging and casting. Forged aluminum wheels are created by compressing and shaping the aluminum alloy under high pressure, resulting in a denser and stronger material. In contrast, cast aluminum wheels are made by pouring molten aluminum into a mold. While cast wheels are generally less expensive, forged wheels provide superior performance and durability.

Carbon Fiber Wheels

Carbon fiber wheels are an innovative option that offers an extremely low weight while maintaining impressive strength. These wheels are particularly favored in high-performance and motorsport applications. However, the high cost of carbon fiber wheels limits their accessibility for average consumers.

Magnesium Wheels

Magnesium wheels are another alternative, known for their lightweight properties. They offer excellent performance benefits but can be prone to corrosion if not properly coated. Magnesium wheels are more commonly found in racing applications due to their lightweight advantage and enhanced performance characteristics.

Fitment and Compatibility Considerations

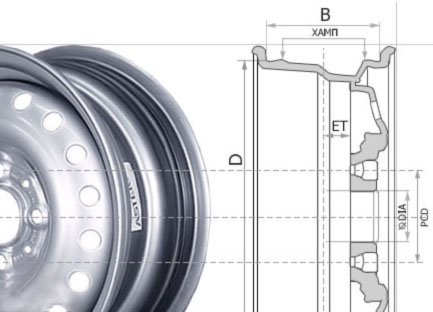

When selecting lightweight wheels, fitment and compatibility with the vehicle’s specifications are critical. This includes considering factors such as size, bolt pattern, offset, and load rating.

Wheel Size

Wheels come in various diameters and widths, which can affect performance and handling characteristics. It is essential to choose a wheel size that is compatible with the vehicle’s suspension setup. Larger wheels can improve cornering and visual appeal but may also lead to a harsher ride.

Bolt Pattern

The bolt pattern must match the vehicle’s hub. It is important to ensure that the selected wheels will fit the specific make and model to avoid compatibility issues.

Offset

Offset describes the distance between the wheel’s hub mounting surface and its centerline. Correct offset is crucial for proper alignment and handling. Using incorrect offset wheels can lead to increased wear on suspension components and tires.

Load Rating

Each wheel has a specified load rating, indicating the maximum weight it can safely support. It is essential to choose wheels that meet or exceed the vehicle’s load requirements to ensure safety and avoid failure.

Installation and Maintenance of Lightweight Wheels

Proper installation and maintenance of lightweight wheels are essential to ensure longevity and performance. Following best practices can prevent common issues.

Installation Tips

When installing lightweight wheels, consider the following:

- Ensure that the hub and wheel surfaces are clean before installation to ensure proper fitment.

- Use a torque wrench to tighten lug nuts to the manufacturer-recommended specifications.

- Consider using wheel spacers or adapters if necessary to achieve proper fitment.

Maintenance Tips

To maintain the performance and aesthetics of lightweight wheels, regular maintenance is crucial. Here are some tips:

- Regular Cleaning: Keeping wheels clean will prevent brake dust and grime buildup, which can lead to corrosion.

- Inspection: Periodically inspect the wheels for cracks, bends, or signs of damage, particularly after racing or harsh driving.

- Correct Tire Pressure: Maintaining the correct tire pressure is vital for optimal performance and safety.

Cost Considerations for Lightweight Wheels

The cost of lightweight wheels can vary significantly based on material, brand, and manufacturing process. Here’s a rough estimate of what to expect:

| Material Type | Price Range | Performance Characteristics |

|---|---|---|

| Steel | $50 – $130 | Durable but heavy |

| Aluminum Alloy (Cast) | $100 – $300 | Lightweight; good performance |

| Aluminum Alloy (Forged) | $300 – $800 | Very lightweight; high performance |

| Magnesium | $500 – $1200 | Ultralight; premium performance |

| Carbon Fiber | $1500 – $3000+ | Exceptional performance; very light |

Conclusion: The Right Choice for Enhanced Performance

Lightweight wheels offer numerous advantages for automotive enthusiasts seeking to enhance the performance of their vehicles. From improved acceleration and handling to better fuel efficiency, the benefits are substantial. However, it is crucial to consider size, fitment, materials, and maintenance when selecting the right lightweight wheels.

Ultimately, investing in quality lightweight wheels can elevate any driving experience, whether on the streets or the racetrack. With careful consideration and informed decision-making, car owners can achieve a perfect balance of performance, safety, and style.

This HTML article provides an in-depth exploration of lightweight wheels, their benefits, materials, fitment considerations, installation and maintenance tips, cost considerations, and concludes by emphasizing the significance of making informed choices.