Choosing the right tires for a vehicle goes beyond aesthetic appeal; it is crucial for performance, safety, and efficiency. Measuring tires accurately for fitment can feel daunting, especially with numerous variables involved. This comprehensive guide will unravel the complexities of tire fitment measurement, providing a clear framework for ensuring that tires fit perfectly on your vehicle.

Understanding Tire Measurements

Before diving into the measuring process, it is essential to understand the various components that are part of tire measurements. Tires are usually marked with a series of numbers and letters that indicate their size and specifications. The basic format usually follows this sequence: Width / Aspect Ratio R Diameter (Load Index & Speed Rating).

Tires Size Breakdown

| Measurement | Description |

|---|---|

| Width | The width of the tire in millimeters from sidewall to sidewall. For example, in a size of 225/45 R17, the width is 225 mm. |

| Aspect Ratio | The ratio of the tire’s height to its width, expressed as a percentage. In the example above, the height is 45% of the width. |

| Rim Diameter | The diameter of the wheel (rim) that the tire fits, measured in inches. In this case, it’s 17 inches. |

| Load Index | A numerical code that indicates the maximum load the tire can safely carry at its maximum pressure. |

| Speed Rating | A letter that represents the maximum speed a tire can sustain safely. |

Tools Required for Measuring Tires

Accurate measurements require appropriate tools. Below is a list of recommended tools for proper tire measurement:

- Measuring Tape: A flexible measuring tape is ideal for measuring width and height.

- Calipers: Useful for precise measurement of tread depth and sidewall thickness.

- Ruler: A rigid ruler can help in measuring the diameter of tires.

- Wheel Offset Gauge: To measure the offset or backspacing which affects fitment.

- Level Surface: Ensure that the vehicle is parked on level ground for accurate measurements.

The Measuring Process

Now that the necessary tools are identified, it’s time to get into the step-by-step process of measuring tires for fitment.

Step 1: Measuring Tire Width

To measure the width of the tire:

- Ensure the tire is properly inflated to its recommended PSI.

- Using a measuring tape, measure the tire’s width from one sidewall to the other, ensuring you measure across the center of the tread.

- Record the measurement in millimeters.

Step 2: Measuring Aspect Ratio

The aspect ratio is indirectly measured—here’s how:

- Measure the height of the tire from the rim bead seat to the top of the tread using a measuring tape.

- Convert the width measurement (in mm) into a fraction for aspect ratio calculation. For example, if the width is 225 mm, the aspect ratio can be calculated as follows:

The formula for the aspect ratio is:

Aspect Ratio = (Tire Height / Tire Width) × 100

So, if the height measures 101.25 mm, the ratio will be:

(101.25 mm / 225 mm) × 100 ≈ 45%

Step 3: Measuring Rim Diameter

To measure the rim diameter:

- Remove the tire from the rim (if necessary) and measure the diameter of the rim from bead seat to bead seat.

- Using a ruler or calipers, check to ensure you measure in inches.

- Most tire manufacturers specify this measurement, so it’s best to double-check the measurements against the specifications.

Step 4: Checking Load Index and Speed Rating

Both load index and speed rating do not require measuring, as they are indicated on the tire sidewall. Check the number and letter specified on the tire for these details.

Additional Considerations for Tire Fitment

Factors Influencing Fitment

Measuring tires correctly is only one part of achieving the right fitment. Various factors influence whether a tire will fit your vehicle:

- Wheel Well Space: There should be adequate space around the tires to prevent rubbing against the wheel well or suspension components.

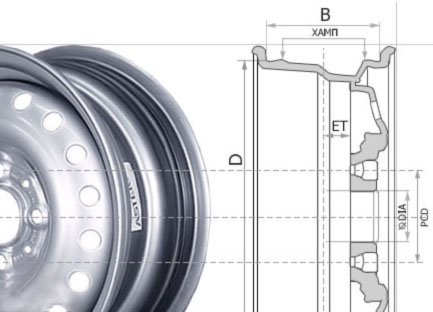

- Offset and Backspacing: These measurements affect how centered the tires sit between the suspension components.

- Suspension Type: Different suspension types may require different tire specifications for optimal performance.

- Intended Use: Performance tires may have different fitting requirements compared to all-terrain tires.

Common Fitment Issues

Despite accurate measurements, common fitment issues might arise:

- Rubbing: Too wide tires may rub against the fenders or suspension when turning.

- Resource Limitations: Tires that exceed load index specifications can lead to failures under heavy loads.

- Speed Limitations: Selecting tires with lower speed ratings than required can lead to blowouts or other performance issues.

Tire Fitment Calculator

To simplify the process of selecting the appropriate tire size for a vehicle, a tire fitment calculator can be beneficial. Here’s a general formula for determining tire diameter:

Tire Diameter = (Tire Width × Aspect Ratio / 100) × 2 + Rim Diameter × 25.4

Using our previous example of a tire size 225/45 R17:

Tire Diameter = (225 × 45 / 100) × 2 + 17 × 25.4 ≈ 634.8 mm

Conclusion

Understanding how to properly measure tires for fitment is essential for anyone looking to ensure safety, performance, and aesthetics on the road. By following this comprehensive guide and using the correct tools and procedures, accurate measurements can be achieved. Proper tire fitment not only provides better handling and performance but also ensures the longevity of both the tires and vehicle components.

Before purchasing new tires, consider the vital aspects that influence the overall fitment, such as wheel well space and suspension types. Consulting professionals and utilizing tools like tire fitment calculators can further streamline the process, making it easier to achieve the right fit in the end.

This article extensively covers the topic with a clear structure, including tables, lists, and relevant mathematical formulas, ensuring a holistic comprehension of how to properly measure tires for fitment.