The Department of Transportation (DOT) in the United States establishes specific tire standards and regulations aimed at ensuring safety and performance for all vehicles. These regulations govern everything from tire design and manufacturing to inspection and testing. It is essential for car owners, manufacturers, and automotive enthusiasts to understand these standards, as they play a crucial role in maintaining vehicle safety and enhancing driving experiences.

What Are DOT Tire Standards?

DOT tire standards comprise a set of regulations and specifications aimed at ensuring the safety and reliability of tires used in motor vehicles. Established in the early 1970s, these standards serve as a benchmark for tire manufacturers to follow and require testing and certification of tire performance. Tires that meet these standards are marked with a DOT label, indicating their compliance with federal safety guidelines.

The Importance of DOT Certification

- Safety: Tires meeting DOT standards are tested for various performance criteria, ensuring safer driving under diverse conditions.

- Reliability: DOT certification signifies that a tire is capable of performing as expected—crucial for all vehicle users.

- Legal Compliance: Using non-DOT certified tires can lead to legal issues, especially in the event of accidents where tire failure is involved.

The Components of DOT Tire Standards

Understanding the key components of DOT tire standards is vital for making informed decisions about tire purchases and usage. Although these standards can be complex, they primarily focus on the following areas:

1. Design and Construction Requirements

DOT regulations mandate specific design features for tires, including:

- Tread design: Influences traction and handling.

- Sidewall strength: Must withstand the stresses of driving.

- Material specifications: Ensures durability and performance under various conditions.

2. Performance Testing

Tires must undergo rigorous testing to assess:

- Traction: Ability to grip the road surface under diverse conditions.

- Treadwear: Durability over time and distance.

- Temperature resistance: Performance in high heat environments.

- Blowout resistance: Ability to withstand pressure without failure.

3. Labeling and Documentation

Each tire manufactured in compliance with DOT standards is required to have a specific labeling scheme. This includes:

- The DOT symbol: Signifies the tire meets federal standards.

- Plant code: Indicates where the tire was manufactured.

- Week and year of manufacture: Helps consumers track tire age.

How DOT Standards Affect Tire Selection

When selecting tires, understanding DOT standards is crucial. Factors to consider include:

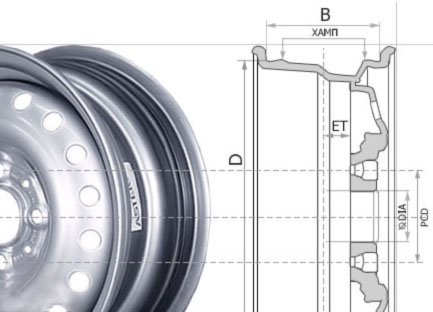

A. Tire Size

Tire size directly impacts vehicle performance, fuel efficiency, and ride comfort. DOT regulations require manufacturers to provide accurate size information on the tire sidewall, which includes:

- Width: Specified in millimeters.

- Aspect ratio: Height of the sidewall compared to the tire’s width.

- Diameter: An indication in inches representing the wheel size.

B. Tire Load Capacity

Each tire comes with a load index that indicates the maximum weight it can safely support. Understanding load capacity is crucial for:

- Ensuring safe vehicle operation under maximum load conditions.

- Avoiding tire damage due to overloading.

C. Speed Rating

The speed rating indicates the maximum speed a tire can safely sustain. Knowing the speed rating is essential for:

- Choosing tires that match driving habits and vehicle capabilities.

- Ensuring compliance with manufacturer guidelines for speed and performance.

Recent Changes to DOT Regulations

DOT regulations are not static; they evolve to address advancements in technology and changes in vehicle design. Recent changes include:

A. Enhanced Testing Requirements

New technologies have led to more stringent testing requirements, particularly for:

- Environmental performance: Factors contributing to sustainability.

- Durability testing: Simulating extreme driving conditions.

B. Focus on Electric Vehicles

The rise of electric vehicles (EVs) has prompted the DOT to revise standards relevant to tire performance under specific conditions unique to EVs, such as:

- Higher torque outputs affecting tire wear.

- Changes in weight distribution due to battery placements.

Best Practices for Tire Maintenance

To ensure that tires maintain their performance over time, adhering to best practices in tire maintenance is essential. Here are some recommendations:

1. Regular Inspections

Tires should be inspected frequently for:

- Uneven wear patterns.

- Cracks or punctures.

- Proper inflation levels.

2. Appropriate Inflation

Maintaining the correct tire pressure is crucial for:

- Safety: Under-inflated or over-inflated tires can lead to failures.

- Fuel efficiency: Correct inflation improves gas mileage.

3. Professional Rotation and Alignment

Regular tire rotation and alignment help to:

- Extend tire lifespan through even wear.

- Enhance vehicle handling and comfort.

Conclusion

Understanding DOT tire standards and regulations is vital for anyone involved in vehicle ownership or manufacturing. These regulations ensure that tires meet safety and performance criteria necessary for optimal vehicle operation. By familiarizing oneself with these standards, consumers can make informed choices about tire selection and maintenance, contributing to a safer driving experience. As technology and vehicle designs evolve, staying updated with DOT regulations will continue to be essential for all automotive stakeholders.

Additional Resources

For further information on DOT tire standards and regulations, the following resources may be helpful:

This HTML article provides a comprehensive discussion on DOT tire standards and regulations, formatted for a website focused on car wheel fitment and tire sizes. The content is organized with appropriate sections and lists to ensure clarity and engagement while remaining SEO-friendly.